Design Brief

‘How Might We’ leverage the scrap recycling industry to help produce a greener/environmentally and economically sustainable coin for the US economy?

Stats and Figures

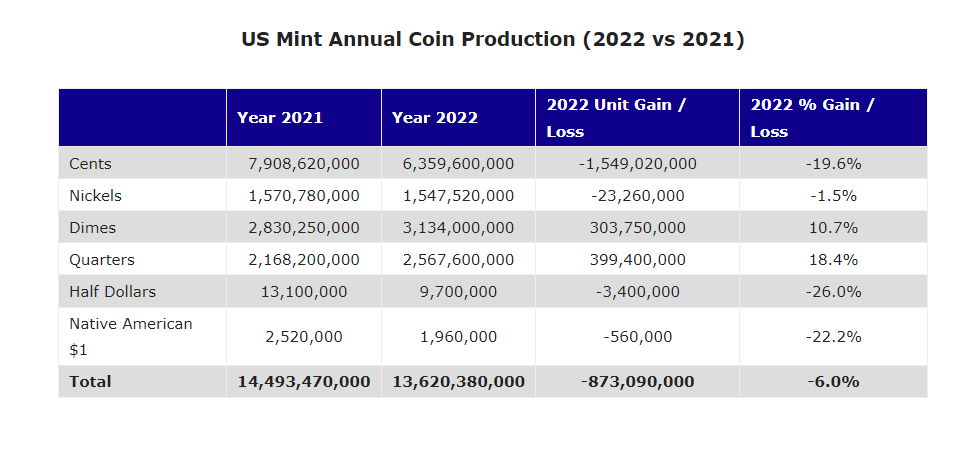

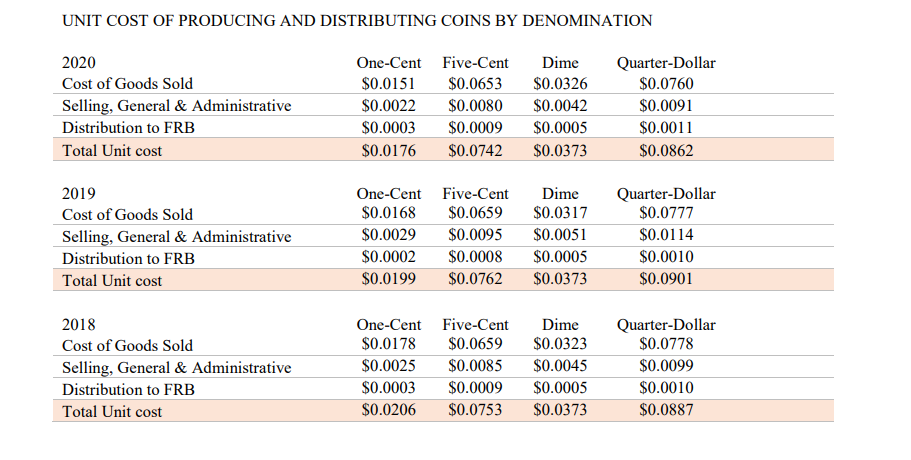

The United States currently mints approximately 13.5 billion new coins annually. These coins are typically composed of alloys containing copper, zinc, and nickel, resulting in the extraction of roughly 22,000 Metric tons of virgin materials from domestic mines every year. This process also contributes significantly to the nation’s carbon footprint. Astonishingly, it costs approximately 1.76 cents to produce a coin with a face value of just 1 cent.

Primary Desk Research

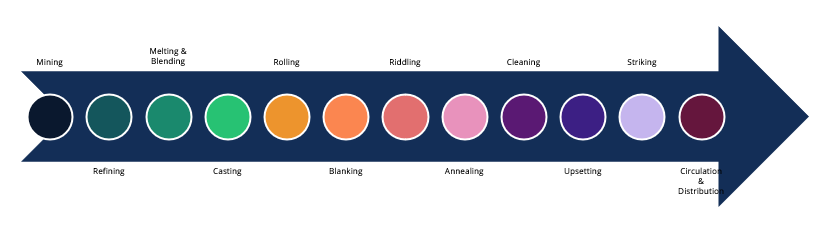

The Coins in the US is economy are predominantly made from Nickle, Zinc and Copper. And these metals are sourced from mines from within the United States. The Minerals are blasted out of the earth, The metals are then refined, followed by melting and blending. This molten metal is then cast into ingots, and then rolled into specifically sized sheets.

Then blanks are cut out of these sheets, followed by the Riddling and Annealing processes. The product from this process is then cleaned to remove all unwanted impurities, and then the upsetting is done. Once these steps are satisfactorily completed, massive amounts of force is applied to the coin, by the use of a die and the graphics and information is pressed into the blank. This then is ready for circulation.

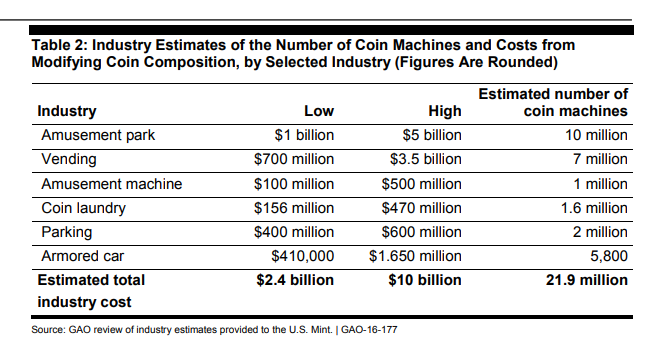

The Mint also records that, the change in composition of the coins to more cost-efficient metals like Steel might result in a great saving to the GOV on an annual basis, in the range of about $8 – $39 Million, but would also result in an implementation cost of nearly $2.4 billion to $10 billion to modify the existing 22 odd million-coin vending machines across the US. Due to this fact, I have taken up this specific research to reduce the carbon footprint and production costs of these coins by using reclaimed metals from the various scrap yards from across the country and re purposing them to satisfy the demand for these coins in the country.

There is not only an economical impact with the production of these coins by a substantial ecological impact as well. It is estimated that the production of 13.5

billion coins would result in the extraction of 22,000 Metric tons of virgin materials from domestic mines every year. These are staggering numbers.

Conclusion

In stark contrast, the United States has made commendable strides in recycling, with the recycling industry producing a remarkable 138 million metric tons of materials in 2018. This initiative has not only been environmentally beneficial but also economically significant, generating an impressive annual economic activity of $109.78 billion.

Considering the 3 metals (Copper, Zinc and Nickle) that are used in the manufacture of coins in the US, as per a report published by USGS in the year 2018 – 861,000 Metric tons of copper was recycled, 165,000 metric tons of Zinc and 124,000 Metric tons of Nickle were reclaimed from scraps. Adding up to an impressive 1,150,000 metric tons of available material. Out of which we would only require 22,000 Metric tons to produce coins and in turn greatly reduce the environmental impact of the production process.

According to an article published by sciencedirect.com 1 tone of recycled Copper costs approximately $3000 when compared to $5500 for the mining of virgin copper, reducing the material costs by at least 40% while also keeping the metal in the circular economy.

According to the US Mint as mentioned above, we could expect a saving between the range of $8 – $39 Million annually by moving to metals like steel and other cheaper allows, but recycling (Urban Mining) on the other hand can result in a saving of nearly $20,250,000. (Formula used: 13.5 billion new coins made per year on average production price of 15 cents per coin- from the figures mentioned in table 3 = $20,250,000) and do not have high implementation costs when compared to moving to new metals like steel.

Improving the efficiency of this process would enable the nation to redirect the resulting extra income toward welfare measures and activities that support those truly in need. By reducing waste and increasing effectiveness, we can reinvest in our communities. This additional revenue could be used to enhance educational programs, helping individuals lift themselves out of poverty and work toward a brighter and more prosperous future.